Process

New Development Process

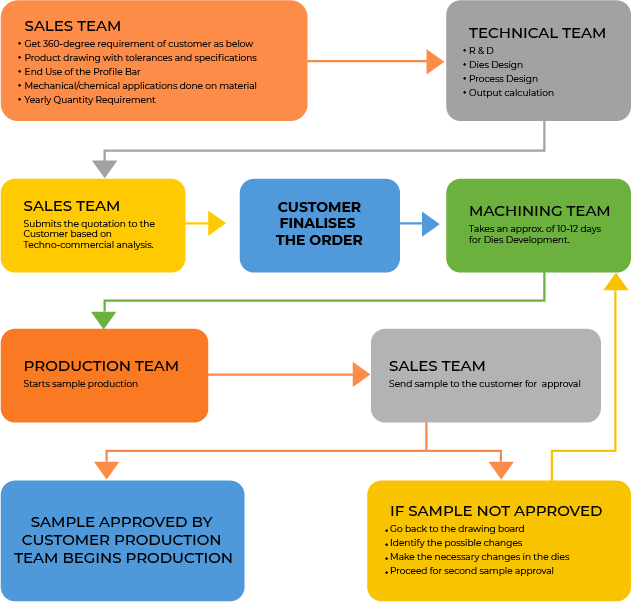

Our New Development Process relies on a 360-degree understanding of customer requirement, product drawing with tolerances and specifications clearly defined, their end use, mechanical/chemical applications done on the material, value required for the customer’s customer and their yearly quantity requirement.

The above information is forwarded by the Sales Team to the Technical Team for preliminary stage R&D which is enough for us to give a ballpark costing for the new development along with the time frame required.

Once the Sales Team seeks ballpark costing approval, the Technical Team goes ahead with complete R&D, including the Dies Design, Process Design and Output calculation.

Thereafter, the Sales Team submits the quotation to the Customer.

Once the order is finalised, our Machining Team takes an approx. of 10-12 days for Dies Development. Once the Dies is developed, sample production starts.

Samples thus developed are sent to the customer for their approval. After approval, full production begins.

However, if customer suggests some changes, we go back to the drawing board, identify the possible changes, make the necessary changes in the Dies and then proceed ahead with second sample approval.